Electronic and technology businesses face pressure to improve energy & sustainability

Geneva, Switzerland, September 30, 2024 – According to a report co-published by the International Telecommunication Union (ITU) and the World Benchmarking Alliance (WBA), the energy consumption of the technology-electronics industry has been steadily rising to meet growing global demands for hardware, network services, data storage, and emerging technologies. However, amid rising global energy costs caused by geopolitical concerns, technology and electronics companies are being driven to implement more sustainable, cost-effective, and long-term energy solutions.

This transition not only helps investors ease their financial burden but also improves long-term competitiveness. However, for this green transition to be successful, it must be done consistently and cohesively throughout the market.

The faster the growth, the higher the electricity burden

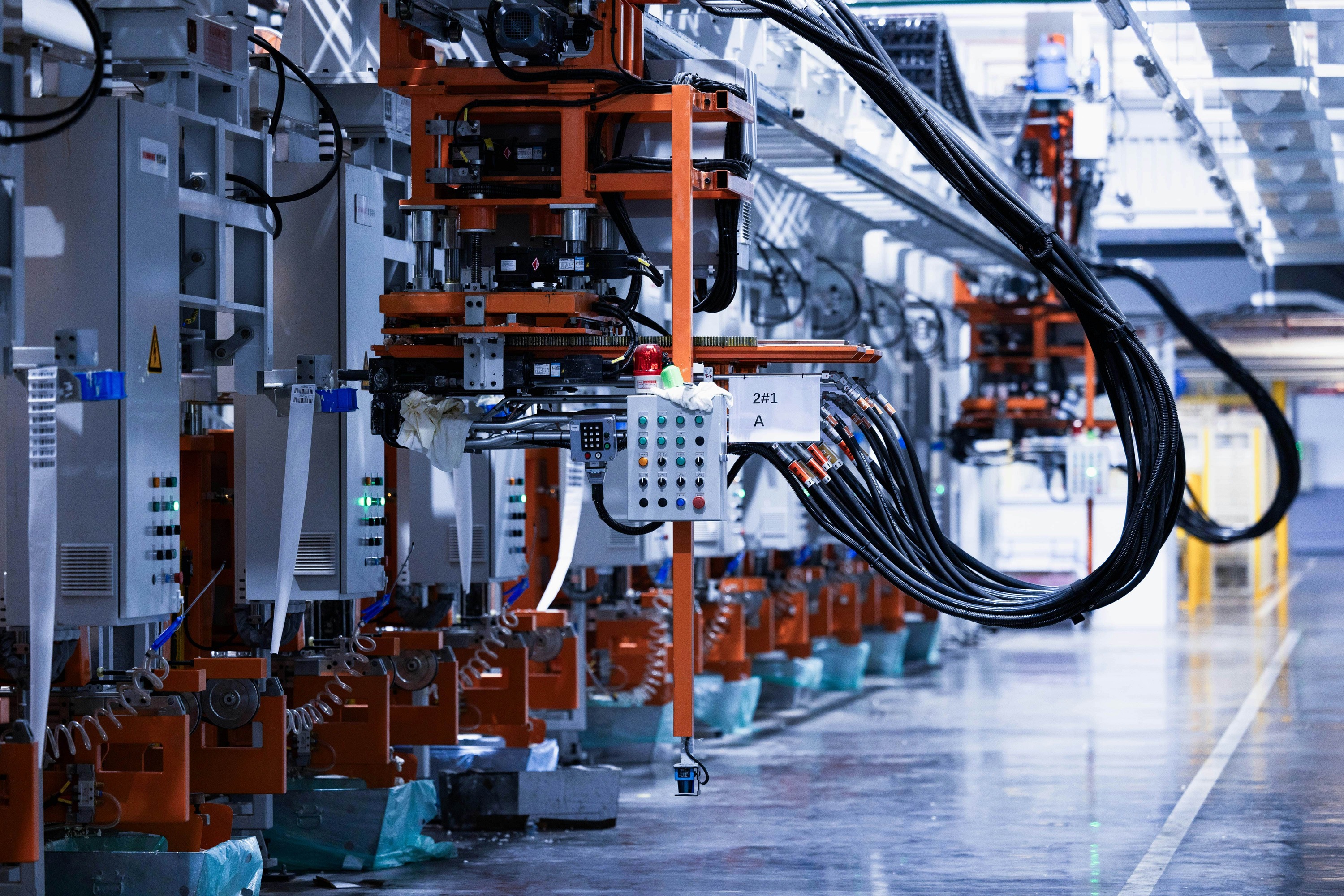

Electronic devices and servers consume massive amounts of electricity, especially for businesses operating in AI, data processing, and high-tech manufacturing. According to NSN, a data center project of approximately 9,300 m² can use as much energy as 15,000 households. As energy costs continue to increase, business owners are facing serious financial pressure. To offset this burden, many will be forced to pass on part of the cost to end consumers or adjust pricing in contracts. The tech-electronics market is experiencing strong growth momentum as countries around the world promote digital transformation across their economies. However, to truly scale in today’s high-cost environment, businesses must start turning to more sustainable energy strategies.

Moreover, frequent reports of power overloads and rolling blackouts in key industrial zones such as Bac Ninh, Hai Phong, and Ho Chi Minh City pose serious risks. In the electronics industry, where even a minute of downtime could result in thousands of faulty components, power stability is not just a utility; it's a business-critical requirement.

Sustainability Pressure from Global Tech Companies

Tech-electronics companies, particularly those that supply devices and components to major tech companies such as Apple, Samsung, LG, and Intel, are facing increasing pressure to meet the sustainability standards set by their partners. Since 2024, many OEM contracts have begun to include ESG (Environmental, Social, and Governance) requirements as a priority.

- Apple requires 100% of its suppliers to shift to renewable energy by 2030. The company has already cut its emissions by 60% since 2015 and now uses more than 17.8 GW of renewable energy across its global supply chain.

- Intel aims to achieve global net-zero emissions by 2040, planning to use 100% renewable electricity and reduce emissions across its value chain.

- Samsung has also introduced strict ESG requirements for its suppliers to ensure sustainable development.

As a result, high-tech industrial zones in Vietnam are now racing to position themselves as "green industrial parks" that meet international standards for environmental and energy management.

Apple has exceeded a 60% reduction in its global greenhouse gas emissions

Rooftop Solar – A Financial and Strategic Sustainability Solution

Installing rooftop solar systems enables tech-electronics manufacturers to address several issues simultaneously. Firstly, the system generates a reliable source of clean electricity, directly powering production, especially during peak hours when grid electricity prices are highest. A rooftop solar system installed by NSN can help factories save between 15% and 40% on annual electricity costs, depending on location and electricity pricing regulations in the area.

Second, using solar energy enables businesses to meet an important ESG reporting requirement by recording "zero emissions" for a portion of their power consumption. This improves their credit scores, facilitates access to international funding, and strengthens relationships with global partners. Many companies now use solar energy as part of their green marketing strategies to build a more sustainable brand image in the high-tech sector.

Finally, companies that choose the Power Purchase Agreement (PPA) can implement this solution without any upfront investment. In this model, NSN fully finances the system and handles design, operation, and legal procedures, while the company only needs to pay a monthly electricity fee at a rate lower than the current EVN price.

NSN: From a traditional industrial EPC general contractor to a comprehensive green energy partner

With more than 22 years of experience, NSN is one of the few businesses in Vietnam that both constructs factories and leads in rooftop solar implementations as an EPC contractor and investor for major tech-electronics brands such as Honda, Toyota, Piaggio, Meiko, and Kyocera etc.

A prime example is the 6 MWp solar rooftop project at Kyocera (Hưng Yên provice), producing approximately 5.7 million kWh/year, saving nearly VND 9 billion in electricity costs and reducing 4,210 tons of CO₂ annually. This project demonstrates why many global manufacturers choose NSN not only for construction but also for renewable energy solutions.

However, NSN emphasizes that green development should not be limited to newly built factories. It must become a shared goal across the entire tech-electronics industry, including existing facilities. These sites make up the majority of the market and will continue operations for another 10-20 years.

According to NSN experts, demand for high-tech solutions in Vietnam will continue to grow, especially as the country becomes an attractive destination for large-scale FDI projects.